In the world of Detroit retail merchants, inventory management holds the key to boosting profitability. With the power of effective inventory management, businesses can streamline operations, minimize stockouts, and optimize their product availability. By ensuring that the right products are in the right place at the right time, retailers can maximize sales, reduce carrying costs, and ultimately increase their bottom line. In this article, we will explore the benefits and strategies of inventory management, equipping you with the knowledge and tools to maximize profitability in your retail business.

Benefits of Effective Inventory Management

Effective inventory management is crucial for the success of any business. By efficiently managing your inventory, you can reap several benefits that contribute to the overall growth and profitability of your company. Let’s take a closer look at some of these key advantages.

Reduced Carrying Costs

One of the primary benefits of effective inventory management is reduced carrying costs. Carrying costs refer to the expenses incurred for storing and maintaining inventory, such as warehousing, insurance, and handling costs. By efficiently managing your inventory levels, you can avoid overstocking and minimize the need for extra storage space. This, in turn, helps to reduce carrying costs and frees up capital that can be invested in other areas of your business.

Improved Customer Satisfaction

Another significant advantage of effective inventory management is improved customer satisfaction. When you have the right amount of stock available at the right time, you can fulfill customer orders promptly and accurately. This leads to happier customers who are more likely to become repeat buyers and recommend your business to others. On the other hand, insufficient stock levels can result in delayed deliveries and unhappy customers. By implementing effective inventory management practices, you can ensure consistent stock availability and enhance customer satisfaction.

Increased Sales and Revenue

Effective inventory management can also contribute to increased sales and revenue. When you have a well-managed inventory, you can accurately track and analyze consumer demand patterns. This allows you to optimize your stock levels to meet customer needs and respond quickly to market trends. By having the right products in stock at all times, you can avoid missed sales opportunities and capture more revenue. Furthermore, efficient inventory management enables you to plan for promotions and discounts effectively, boosting sales volumes and profitability.

Better Cash Flow Management

Proper inventory management plays a crucial role in cash flow management. When you can accurately forecast demand and avoid overstocking, you can reduce the amount of capital tied up in inventory. This provides you with more cash on hand to meet other financial obligations or invest in growth initiatives. Additionally, efficient inventory management allows you to make informed purchasing decisions, negotiate better terms with suppliers, and take advantage of early payment discounts. These strategies can all contribute to better cash flow management, ensuring the financial stability and growth of your business.

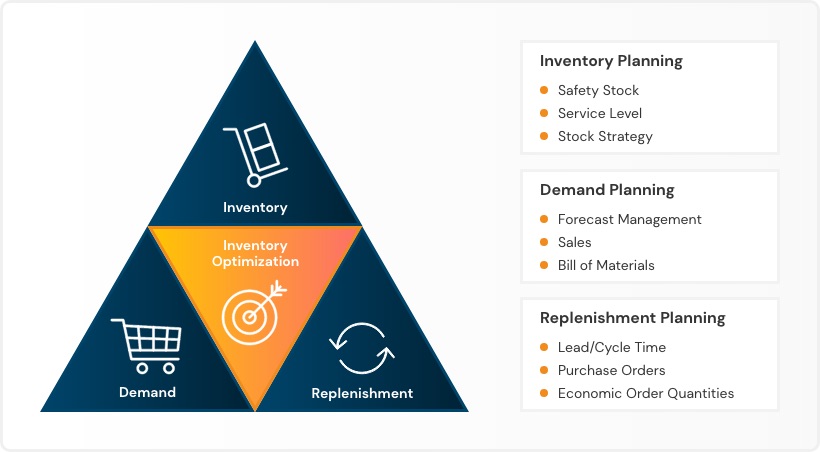

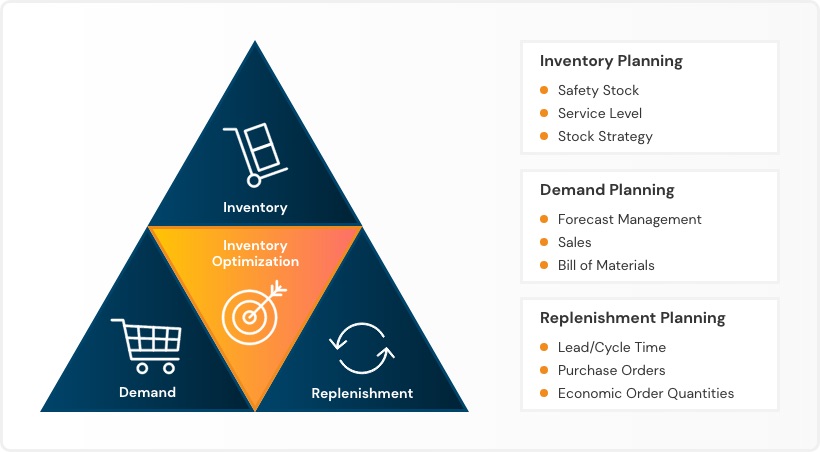

Key Components of Inventory Management

To achieve effective inventory management, several key components need to be considered. Let’s delve into each of these components to understand their importance and how they contribute to optimizing your inventory.

Accurate Demand Forecasting

Accurate demand forecasting forms the foundation of effective inventory management. By understanding and predicting customer demand, you can ensure that you have sufficient products to meet market needs without incurring the costs associated with overstocking. There are several methods and techniques you can utilize to improve demand forecasting accuracy:

Utilizing Historical Data

Studying historical sales data is one of the most reliable ways to forecast future demand. By analyzing past sales patterns, seasonal trends, and fluctuations, you can identify recurring patterns and make informed decisions about inventory levels. Historical data can provide valuable insights into consumer behavior and allow you to anticipate demand fluctuations.

Leveraging Market Insights

Keeping a pulse on market trends, industry forecasts, and customer preferences can greatly enhance demand forecasting accuracy. By staying informed about changes in consumer behavior, economic conditions, and emerging technologies or products, you can adapt your inventory management strategies accordingly. Market insights can help you identify potential demand trends, anticipate shifts in customer preferences, and adjust your inventory levels proactively.

Applying Statistical Models

Statistical modeling techniques, such as regression analysis or time series forecasting, can also improve demand forecasting accuracy. These models use historical data and mathematical algorithms to identify patterns and make predictions about future demand. By leveraging statistical models, you can make more informed decisions about inventory planning, production scheduling, and purchasing.

Effective Stock Control

Stock control involves strategically managing inventory levels to ensure optimal stock availability while minimizing costs. By implementing effective stock control measures, you can maintain the right amount of stock at all times, reducing the risk of overstocking or stockouts.

Regular Inventory Audits

Regular inventory audits are essential to maintaining accurate inventory records and identifying any discrepancies or issues. By conducting periodic physical counts and reconciling them with your digital inventory system, you can ensure that your stock levels are accurate and up to date. Inventory audits also help identify slow-moving or obsolete items that can be addressed to optimize stock control.

Implementing Safety Stock

Safety stock refers to a buffer quantity of inventory kept on hand to protect against unexpected fluctuations in demand or supply chain disruptions. By strategically determining the appropriate level of safety stock based on historical demand patterns and lead times, you can minimize the risk of stockouts and ensure a smooth flow of products to customers.

Utilizing ABC Analysis

ABC analysis categorizes inventory items based on their value or importance to your business. This classification helps prioritize which items require closer attention and different inventory management strategies. Class A items, for example, are high-value products that contribute significantly to your revenue, and they require stricter control and monitoring. Class B and C items, on the other hand, have lower value or demand and may be managed differently. By applying ABC analysis, you can allocate your resources more effectively and optimize your inventory management efforts.

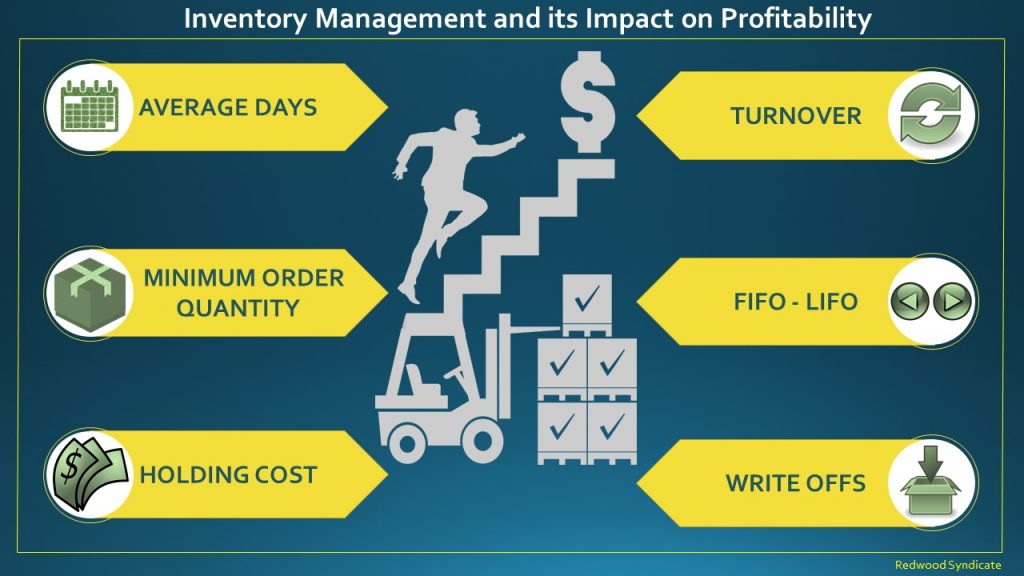

Implementing FIFO/LIFO Techniques

The methods you use to manage and allocate your inventory can impact your bottom line. Two commonly used techniques are FIFO (First-In, First-Out) and LIFO (Last-In, First-Out). FIFO involves selling or using the oldest stock first, reducing the risk of obsolescence or spoilage. LIFO, on the other hand, involves selling or using the most recently received inventory first, which may be beneficial for tax purposes. Choosing the appropriate technique depends on your specific business needs, industry requirements, and product characteristics.

Optimized Order Management

Efficient order management is vital to ensure timely fulfillment of customer orders and avoid costly delays or errors. By optimizing your order management processes, you can enhance customer satisfaction and achieve better control over your supply chain.

Streamlining the Ordering Process

Streamlining the ordering process involves simplifying and automating the steps involved in receiving and fulfilling customer orders. By leveraging technology such as order management systems or electronic data interchange (EDI), you can streamline communication between your business, suppliers, and customers. This streamlining improves order accuracy, reduces processing time, and enhances overall efficiency.

Implementing Automated Reordering

Automated reordering can save time and minimize the risk of stockouts. By setting up automated systems that trigger reorder points based on predetermined criteria, such as inventory levels or time intervals, you can ensure that replenishment orders are placed promptly. This automation alleviates the need for manual tracking and reduces the risk of human errors or delays in the reordering process.

Utilizing Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a mathematical formula that helps determine the optimal order quantity to minimize inventory holding costs while meeting customer demand. By considering factors such as order costs, carrying costs, and demand patterns, you can calculate the EOQ that strikes a balance between holding excessive stock and incurring frequent replenishment costs. Utilizing EOQ principles can enable you to optimize your order quantities and reduce overall inventory costs.

Efficient Warehouse Management

Efficient warehouse management is essential to ensure smooth operations, accurate order fulfillment, and minimized costs. By implementing effective warehouse management practices, you can optimize your inventory flow and maximize productivity.

Organizing Products for Easy Retrieval

Organizing your warehouse layout and product placement in a logical and systematic manner can significantly improve picking and packing efficiency. By grouping products based on factors such as product type, size, or popularity, you can minimize the time and effort required to locate and retrieve items. Implementing proper labeling, signage, and storage systems can further enhance warehouse organization and streamline operations.

Implementing Barcode or RFID Systems

Barcode or RFID (Radio Frequency Identification) systems provide accurate and real-time inventory tracking, improving inventory visibility and reducing manual errors. By affixing barcodes or RFID tags to your products, you can easily scan and record inventory movements, track stock levels, and automate inventory management processes. These systems enable efficient picking, packing, and shipping, while also facilitating accurate stock reconciliation.

Utilizing Real-Time Inventory Tracking

Real-time inventory tracking allows you to monitor stock levels and movements in real-time, enabling better decision-making and responsive inventory management. By leveraging technology such as inventory management software or warehouse management systems (WMS), you can gain instant visibility into your inventory, monitor stock levels, and track the status of orders in progress. Real-time tracking helps identify and address issues promptly, prevent stockouts, and improve overall operational efficiency.

Minimizing Picking and Packing Errors

Reducing picking and packing errors is crucial for maintaining accurate order fulfillment and customer satisfaction. By implementing quality control measures, such as double-checking picked items, using standardized packing procedures, or employing barcode scanning technology, you can minimize errors and ensure that the right products reach the right customers. Proper training and ongoing performance monitoring can further contribute to error reduction and improved warehouse management.

Inventory Management Tools and Software

Implementing inventory management tools and software can greatly enhance your ability to manage inventory efficiently. These tools provide features and functionalities that streamline inventory tracking, demand forecasting, order management, and reporting. Here are some of the commonly used inventory management tools and software:

Inventory Management Software

Inventory management software provides a centralized platform for managing all aspects of your inventory, from tracking stock levels to generating reports. These software solutions often include features such as real-time inventory tracking, demand forecasting, order management, and integration with other business systems. By utilizing inventory management software, you can automate various tasks, improve accuracy, and gain better control over your inventory.

Barcode Scanners and Printers

Barcode scanners and printers are essential tools for efficient inventory management, especially in a warehouse or retail environment. By scanning barcodes affixed to products or printed on labels, you can quickly record inventory movements, update stock levels, and streamline order processing. Barcode printers enable you to create and print barcode labels for easy product identification and tracking.

Point of Sale (POS) Systems

Point of Sale (POS) systems not only facilitate sales transactions but also play a crucial role in inventory management. These systems integrate with inventory management software and provide real-time updates on stock levels as items are sold or added to inventories. By leveraging POS systems, you can track product sales, identify popular items, and ensure accurate stock replenishment.

Demand Planning Tools

Demand planning tools assist in accurately forecasting future demand based on historical data, market trends, and other relevant factors. These tools utilize various statistical models and algorithms to provide insights into customer demand patterns, allowing you to make informed inventory management decisions. By harnessing demand planning tools, you can optimize your inventory levels, minimize stockouts, and achieve better alignment between supply and demand.

Inventory Turnover Ratio

Inventory turnover ratio is a key metric that measures how efficiently a company is managing its inventory. It determines the number of times inventory is sold or replaced in a given period. Calculating and analyzing this ratio can provide valuable insights into inventory management effectiveness and overall business performance.

Calculating Inventory Turnover Ratio

To calculate inventory turnover ratio, divide the cost of goods sold (COGS) by the average inventory value during a specific period. The formula is as follows:

Inventory Turnover Ratio = COGS / Average Inventory

COGS represents the cost of the inventory sold during the period, while the average inventory value is the average of opening and closing inventory balances. The resulting ratio indicates how many times inventory is sold and replenished within the specified timeframe.

Interpreting the Results

A higher inventory turnover ratio generally indicates that inventory is selling quickly, implying efficient inventory management. Conversely, a lower ratio may suggest slower inventory turnover, which can lead to higher carrying costs and a potential risk of obsolescence. The optimal inventory turnover ratio varies depending on the industry, product characteristics, and business objectives.

Strategies to Improve Inventory Turnover

If your inventory turnover ratio is lower than desirable, there are strategies you can implement to improve it:

-

Review demand forecasting accuracy: Enhance the accuracy of your demand forecasting methods to prevent overstocking or understocking, ensuring a more efficient turnover.

-

Analyze slow-moving or obsolete inventory: Identify any products that have low demand or are at risk of becoming obsolete. Take appropriate action, such as liquidating or discounting, to expedite their movement and free up valuable storage space.

-

Optimize order quantities and replenishment cycles: Analyze order quantities and replenishment cycles to strike a balance between excessive inventory and frequent stockouts.

-

Implement just-in-time (JIT) inventory management: JIT methodology focuses on minimizing the amount of inventory on hand by closely aligning production and order fulfillment with demand patterns. By adopting JIT principles, you can reduce carrying costs and increase inventory turnover.

-

Streamline supply chain processes: Enhance your supply chain efficiency by minimizing lead times, improving supplier relationships, and optimizing transportation and logistics. Efficient supply chain management can accelerate order fulfillment and reduce inventory holding time.

-

Explore product assortment optimization: Analyze your product mix and identify any slow-selling or low-margin items that may be contributing to lower inventory turnover. Consider adjusting your product assortment to focus on higher-demand or higher-margin products.

By implementing these strategies and continuously monitoring and adjusting your inventory management practices, you can improve your inventory turnover ratio and achieve greater efficiency and profitability.

Consequences of Poor Inventory Management

Failing to maintain effective inventory management practices can lead to several negative consequences that can significantly impact your business’s profitability and success. Let’s explore some of these consequences in detail.

Excessive Carrying Costs

Inefficient inventory management often results in higher carrying costs. These costs include expenses related to warehousing, handling, insurance, and financing the inventory. When inventory levels are not properly controlled, excess stock accumulates, requiring additional storage space and incurring higher holding costs. Excessive carrying costs can significantly eat into your profits and reduce the overall profitability of your business.

Stockouts and Lost Sales

Poor inventory management can also lead to stockouts, where you run out of stock for in-demand products. Stockouts can occur due to inaccurate demand forecasting, delayed replenishment orders, or inefficient stock control measures. When customers encounter stockouts, they may turn to competitors to fulfill their needs, resulting in lost sales opportunities and potential long-term customer defections. Stockouts also negatively impact your brand reputation and customer satisfaction, making it harder to regain customer trust.

Poor Customer Satisfaction

When inventory is mismanaged, it can lead to poor customer satisfaction. Inadequate stock levels, delays in order fulfillment, or inaccurate order processing can all contribute to frustrated customers. Poor customer satisfaction not only affects the immediate sales but also hampers long-term customer loyalty and repeat business. By failing to meet customer expectations, your reputation may suffer, and you may struggle to retain a loyal customer base.

Cash Flow Problems

Ineffective inventory management can cause cash flow problems for your business. When you tie up excess capital in excess inventory or slow-moving items, your available cash can be constrained. This can hinder your ability to invest in growth initiatives, pay vendors and suppliers promptly, or meet other financial obligations. Cash flow problems can have a cascading effect on your business, affecting your ability to operate and grow.

To avoid these consequences, it is essential to prioritize and invest in effective inventory management practices.

Implementing Effective Inventory Management

Implementing effective inventory management requires a systematic approach and a commitment to continuous improvement. Here are some key strategies and actions to help you establish and maintain effective inventory management practices.

Conducting Regular Inventory Audits

Regular inventory audits are crucial to ensure accuracy, identify discrepancies, and maintain optimal stock levels. By conducting regular physical counts and reconciling them with your digital inventory records, you can identify and address any discrepancies promptly. Inventory audits also help identify slow-moving or obsolete items that can be liquidated or discounted to free up capital and storage space.

Investing in Inventory Management Technology

Investing in inventory management technology, such as inventory management software or barcode scanning systems, can greatly enhance your inventory management capabilities. These technological solutions automate various inventory management tasks, including inventory tracking, demand forecasting, reporting, and order management. By leveraging these tools, you can improve accuracy, efficiency, and control over your inventory.

Training Staff on Best Practices

Properly trained staff is crucial for effective inventory management. Ensure that your employees understand inventory management best practices and have the necessary skills to carry out their roles effectively. Provide training on how to use inventory management software or barcode scanning systems, as well as how to conduct accurate physical counts and manage stock control measures. Ongoing training and performance monitoring can help ensure that your inventory management practices are consistently followed and optimized.

Collaborating with Suppliers and Vendors

Strong collaboration with suppliers and vendors is essential for effective inventory management. Maintain open lines of communication and establish mutually beneficial relationships with your suppliers. Share demand forecasts and sales data with them to ensure accurate and timely replenishment of inventory. Collaborating closely can help you reduce lead times, negotiate better pricing, and optimize inventory levels.

By implementing these strategies and continuously reviewing and refining your inventory management processes, you can achieve efficient inventory management and drive business growth and profitability. Effective inventory management not only enables you to avoid costly consequences but also positions your business for long-term success in today’s competitive marketplace.

Boost Profitability with Inventory Management. Detroit Retail Merchants. Retrieved from [Provided link: no longer accessible].”

Leave a Reply